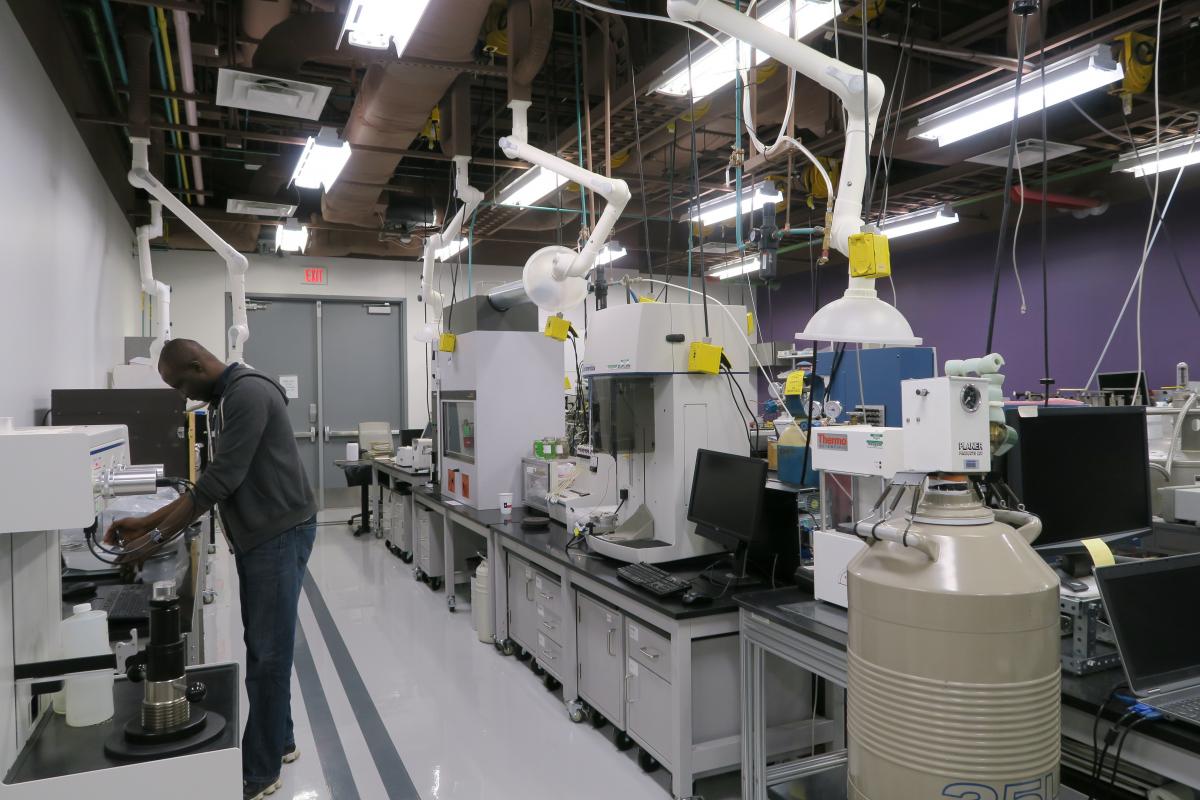

This lab is used for fabrication and study of bio products which can include wood products, bio composites, activated carbon, and any materials made from renewable resources. The lab is used to prep materials and construct composites. Currently in the lab is a concrete tester, a differential scanning caloromiter, a plasma etcher, and some other equipment most of which is used to characterize the material properties of what is made in the lab. Most characterization is specific to properties that are important most bioproducts. A seconday Lab to this space is D140 where this lab is stores the large box furnace, tube furnace, large universal testing machine, and wind tunnel senior design project. The furnaces are used to activate materials into complex carbon structures or modify materials with heat treatments. Much of the research done in D140 is linked to lab D144.