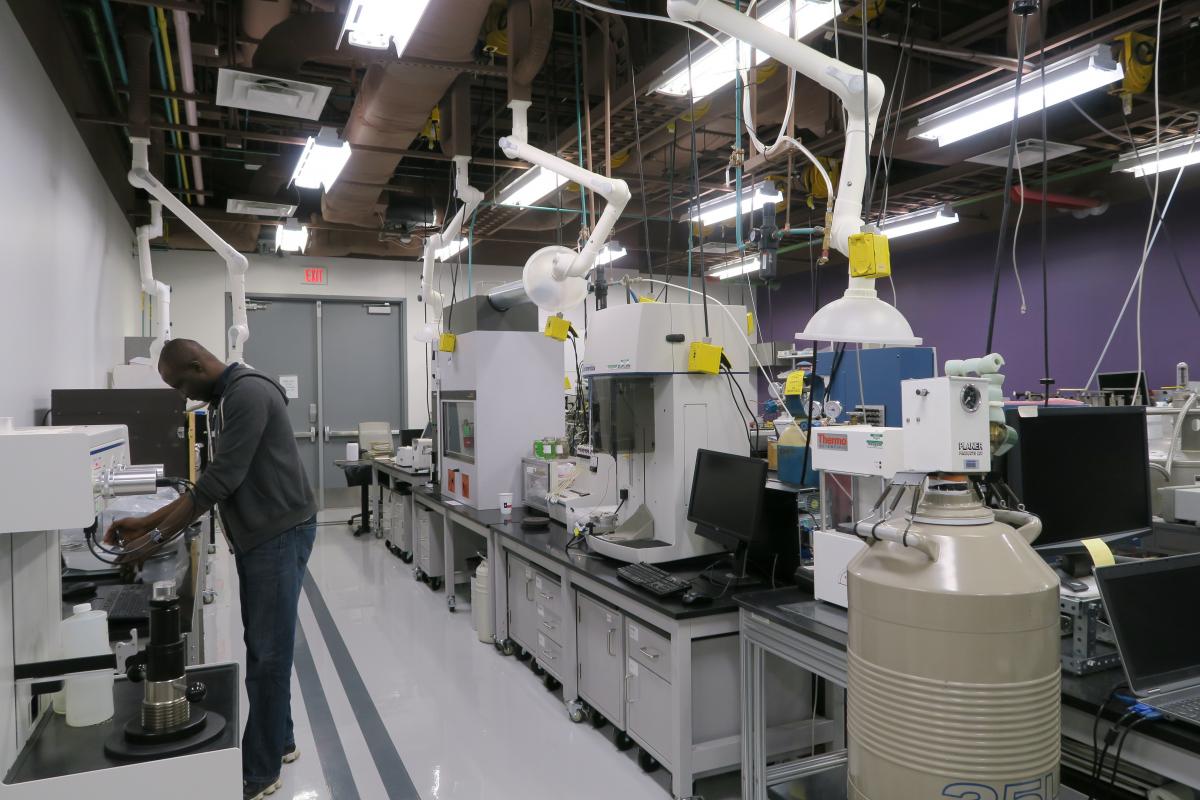

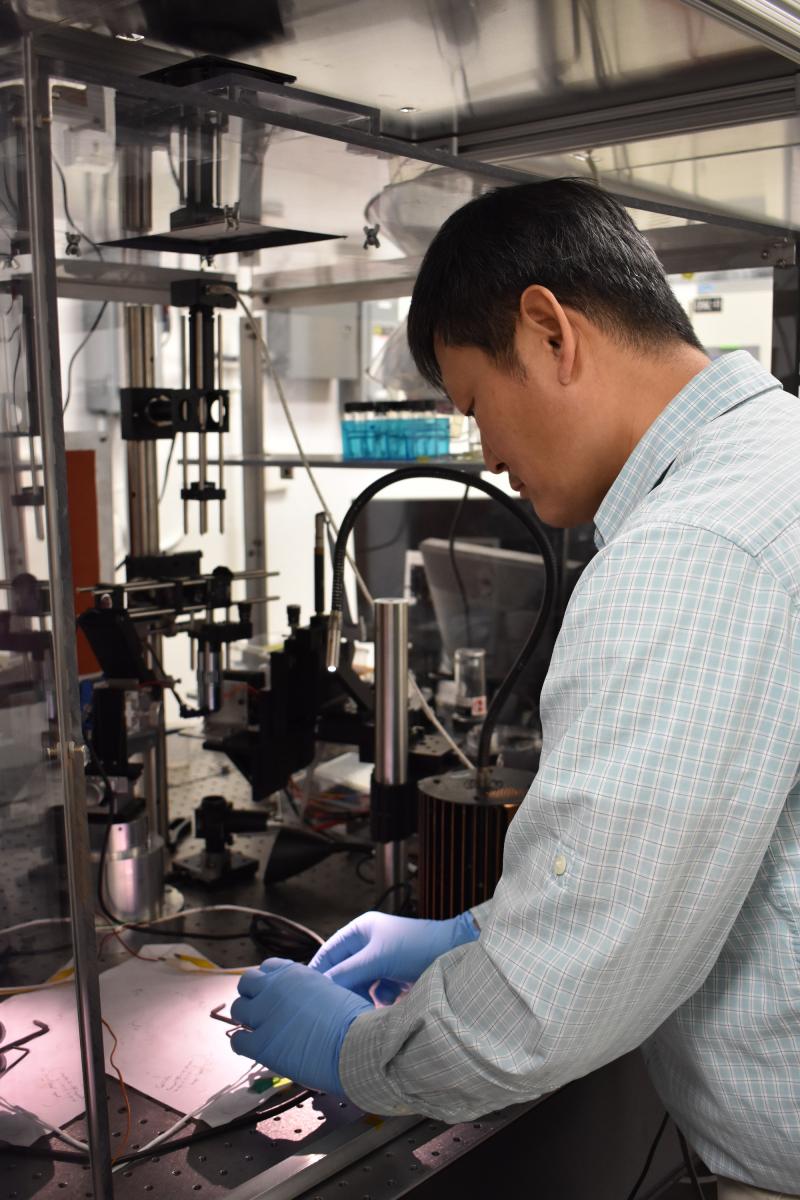

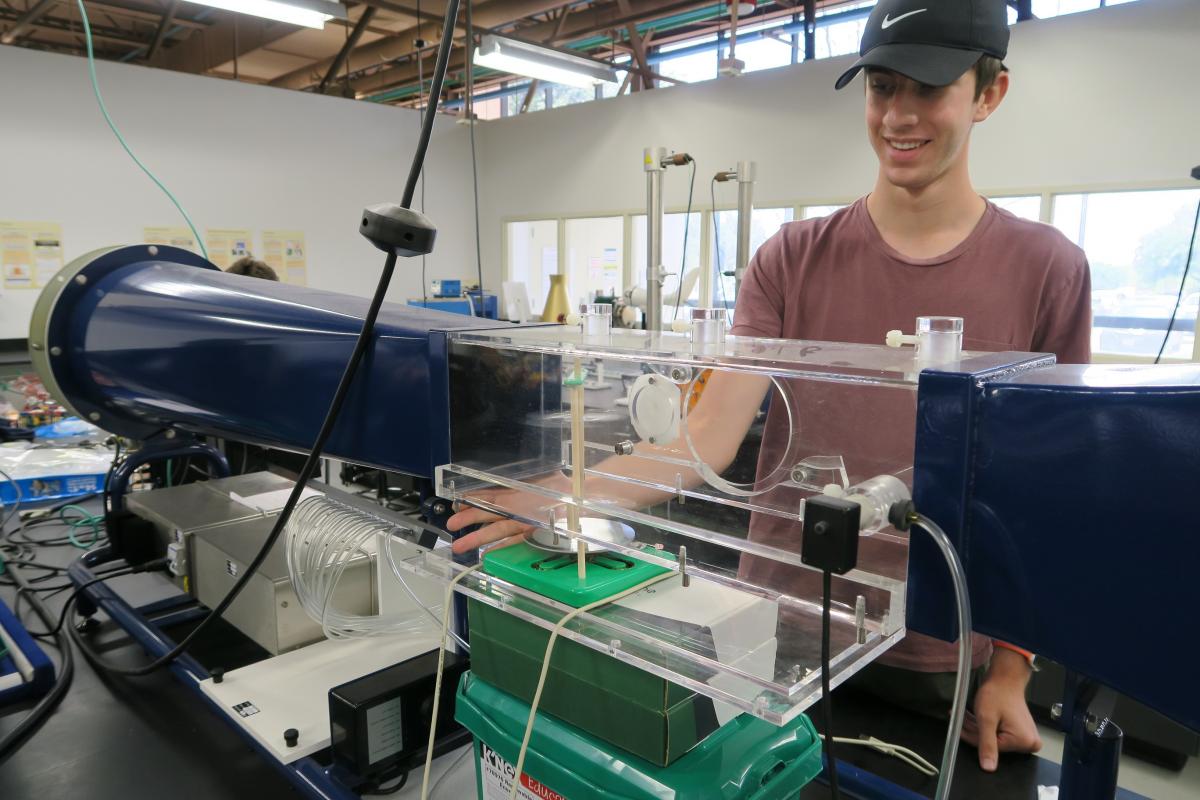

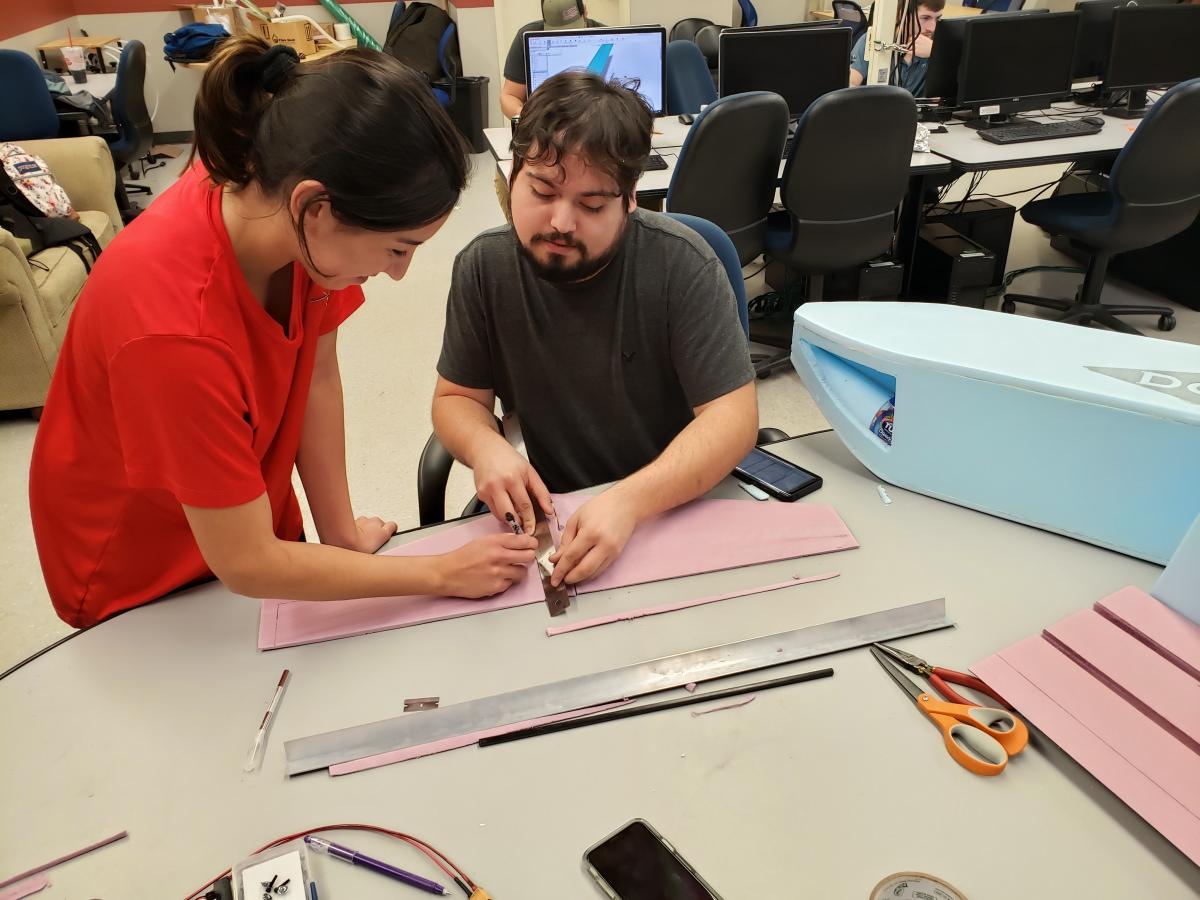

Research and innovation are integral parts of the Mechanical Engineering department at The University of North Texas, a Carnegie Tier One research institution. The department offers state-of-the-art facilities ranging from a variety of instructional laboratories to research facilities including the Net Zero Energy (ZØE) Research Laboratory. These facilities allow our faculty and students to work side-by-side on industry-sponsored senior capstone design projects or on cutting-edge graduate research.

The department’s research focus include energy and the environment, sustainable products and manufacturing systems, biotechnology, nanotechnology, materials for energy storage, advanced manufacturing, and renewable energy systems. Faculty, post-doctoral researchers and student teams work on exciting inter-disciplinary projects on robotics and controls, manufacturing of composite and engineered materials, characterization of high-performance structural material, air quality modeling and environmental monitoring. They are also developing next-generation sensors for extreme environments, and energy harvesting using phase-change materials. If you are interested in partnering with the ME Department or if you are a prospective graduate student, email us at mechanical@unt.edu or contact the department at 940-565-2400.