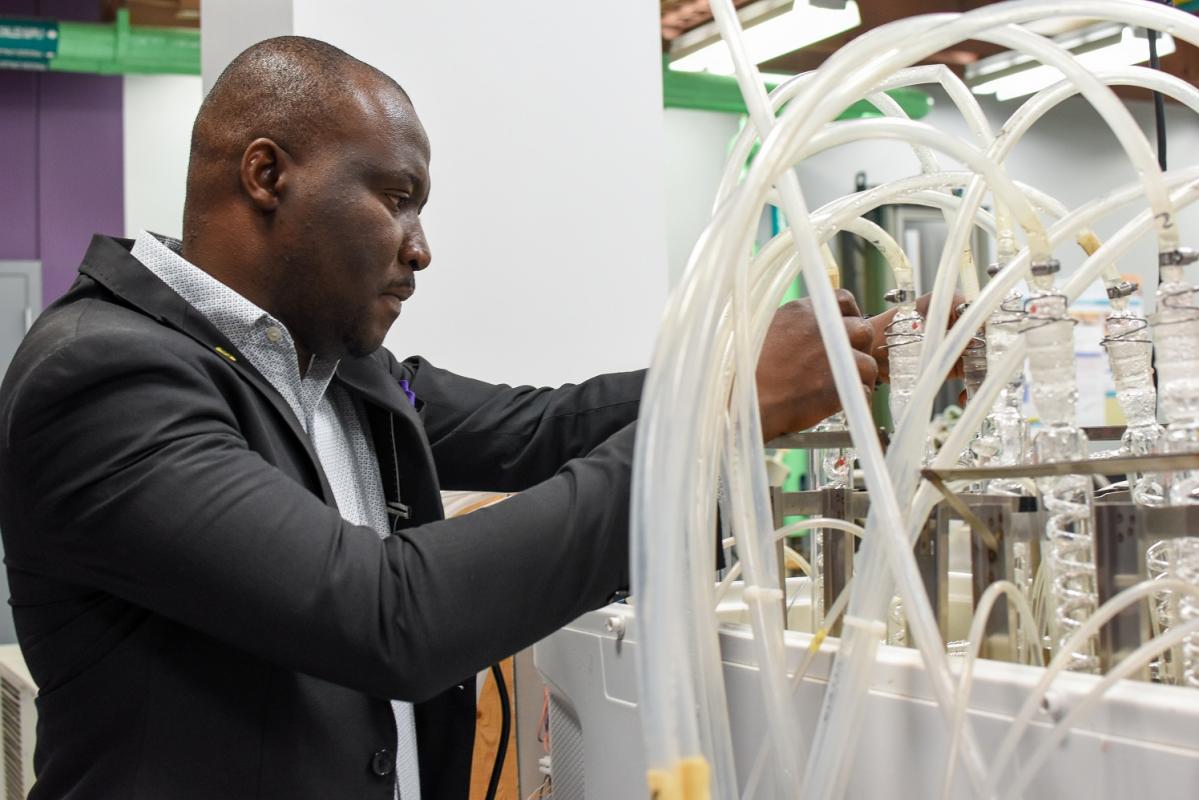

Kayode Oluwabunmi, a doctoral student in the Department of Mechanical & Energy Engineering, is researching Poly-Lactid Acid (PLA) polymer foams for use as insulation in buildings under the guidance of Associate Dean for Undergraduate Studies Nandika D’Souza. His work recently received second place in the 2019 SPE Automotive Composites Conference & Exhibition poster category B.

When compared to conventional insulation foams, PLA foams are more cost-effective and have a lower carbon footprint as they require less energy and are made of bio-resourced polymers.

“In terms of consumer health, recycling, and disposal challenges, all can be mitigated in the long-run provided the bio-resourced foams are used extensively and the raw materials used in producing them are abundant,” said Oluwabunmi.

Oluwabunmi uses functionalized cellulose fibrils made from wheat husks and soy bean hulls as inclusions in bioresourced PLA foams – which is made from corn – as opposed to the currently used conventional polyurethane, which do not.

“We are reinforcing the foams with cellulose fibrils. Cellulose fibrils have an inherent hollow internal structure that is responsible for its desirable low thermal conductivity value,” said Oluwabunmi. “Using a precise and accurate concentration of cellulose inclusions in PLA will definitely make the resulting composites more sustainable and comparable in performance relative to the conventional foams and would also make them very biodegradable when landfilled at the end of their lives.”